A big step towards sustainability: NirvanaBelt’s waterless fabric printer

It is well known that the textile industry is among the worst for water waste and pollution.

Traditionally digital printing and dyeing methods have contributed to this problem. This is especially true for printing on natural fabrics, where aggressive chemicals are often used, before and/or after steaming and washing in order to meet quality requirements. The process is chemically intensive, consumes high amounts of energy and results in large volumes of polluted waste water. We estimate that for each sqm of fabric printed, it currently takes up to 150L of water to print on.

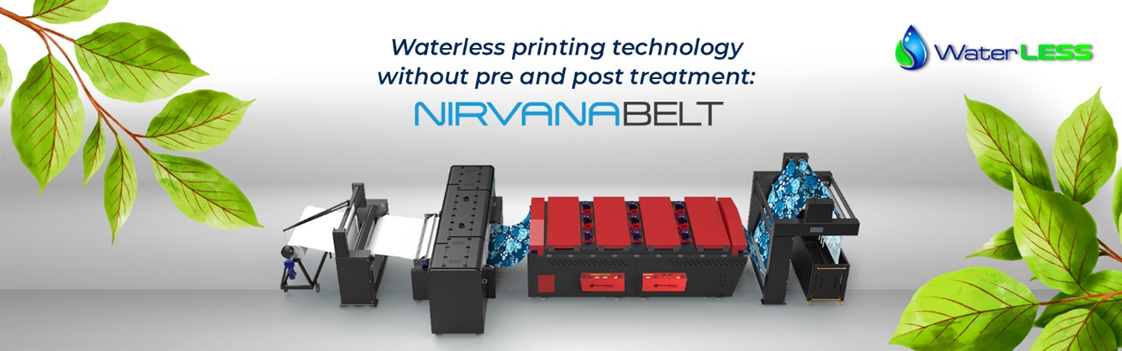

That’s all about to change with Optimum Digital’s new NirvanaBelt printer. This set up, developed in accordance with our 2030 Green Initiative Goals, eliminates the need for any pre or post treatment, steaming or washing, without sacrificing the quality and fastness that currently necessary.

With the new Optimum Eco-Pigment ink solution, the results speak for themselves. Vibrant colors and detailed images are printed with 32 print heads doing 2 pass at 5,166sqft/hr. The fastness compares to existing methods, and so does the croc. And the hand-feel is equally great.

For the first time, printing waterlessly also makes a lot of business sense. Eliminating the need for pre-treatment and water, not only reduces the required machinery (saving on upfront cost) but also the ongoing sqm cost associated with high utility bills and treatment chemicals. Not to mention having to deal with production waste management.

We’re proud that the NirvanaBelt is becoming the latest innovation to empower textile manufacturers to achieve sustainable digital printing. Get in touch if you want to find out more.