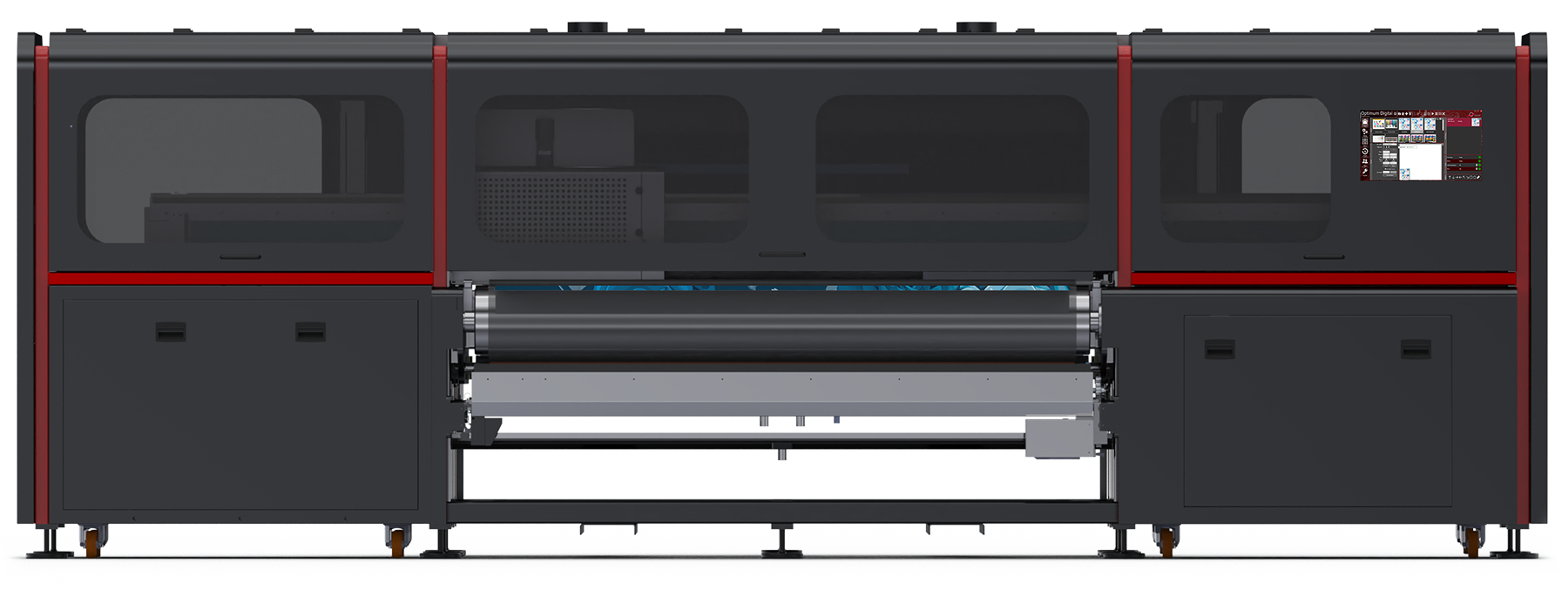

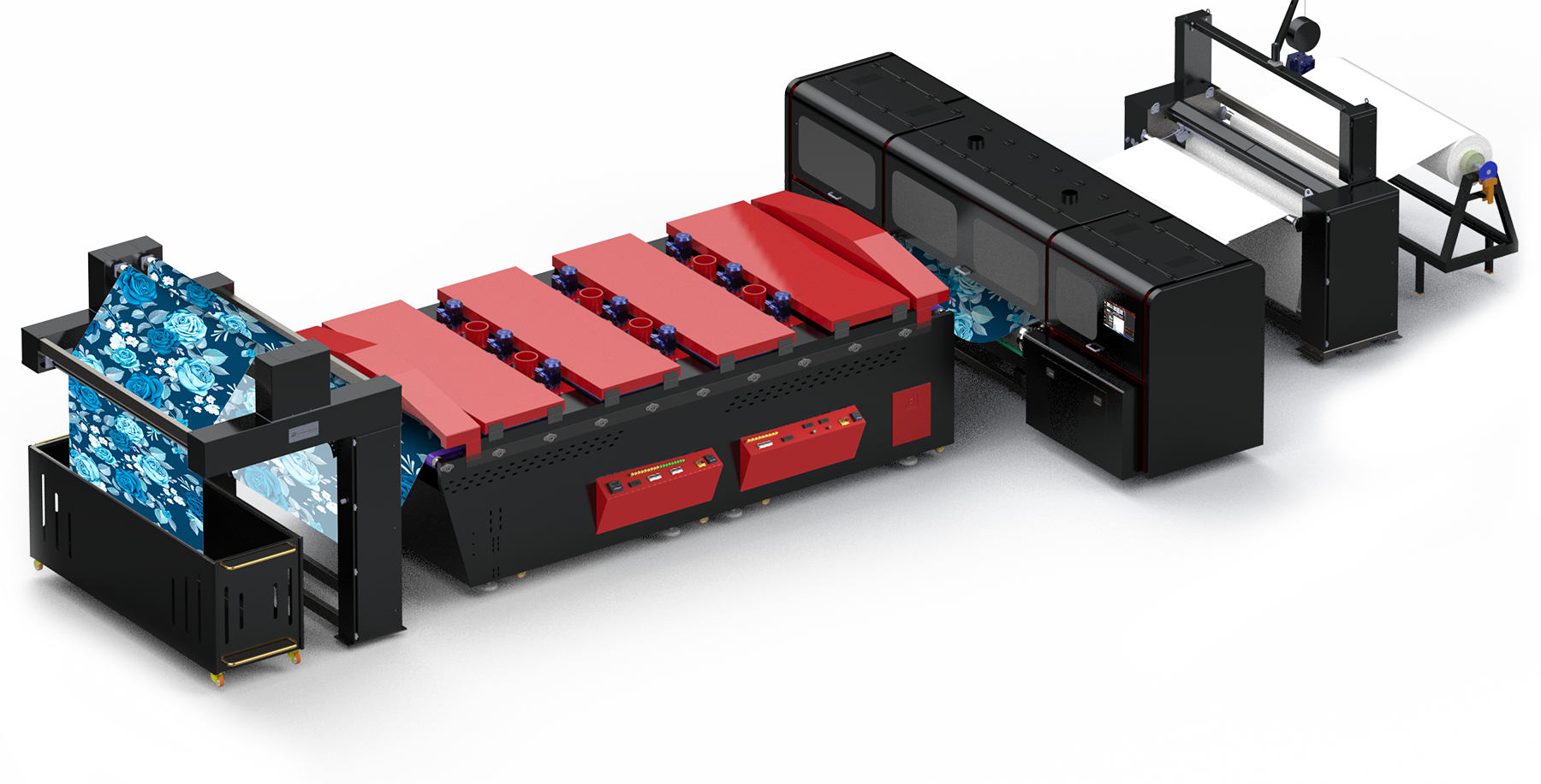

FLAGSHIP TEXTILE BELT PRINTER CONFIGURED, WITH A STICKY BELT, FOR QUALITY DIRECT PRINTING ON ELASTIC AND INELASTIC FABRICS

8611 sqft/hr

Max Speed

Up to 8 vibrant

Color Options

80.7”

Media Width

Why choose

- Fully waterless printing process on non-pretreated cotton

- Detailed and colorful prints with up to 32 print heads in 8 color rows

- This 6,000lbs strong and high quality build allows for hands-off uninterrupted operations 24/7

- Flexible media options to meet for a large variety of elastic and non-elastic prints

- From the machinery to our after sales services we always provide the highest quality product at competitive industry prices

- All new printers come with a one-year full warranty apply with full support from our in-house leading color specialists and technical service engineers

Print Speed

2 Row CMYK

- 0 sqft/hr

- 1291 sqft/hr

- 1937 sqft/hr

- 2583 sqft/hr

- 4305 sqft/hr

4 Row CMYK

- 0 sqft/hr

- 2583 sqft/hr

- 3875 sqft/hr

- 5166 sqft/hr

- 8611 sqft/hr

2 Row CMYK +2

- 0 sqft/hr

- 1291 sqft/hr

- 1937 sqft/hr

- 2583 sqft/hr

- 4305 sqft/hr

4 Row CMYK +2

- 0 sqft/hr

- 2583 sqft/hr

- 3875 sqft/hr

- 5166 sqft/hr

- 8611 sqft/hr

2 Row CMYK + 4

- 0 sqft/hr

- 1291 sqft/hr

- 1937 sqft/hr

- 2583 sqft/hr

- 4305 sqft/hr

4 Row CMYK + 4

- 0 sqft/hr

- 2583 sqft/hr

- 3875 sqft/hr

- 5166 sqft/hr

- 8611 sqft/hr

TECHNICAL SPECIFICATIONS

| Default Printhead | Konica Minolta 1024i |

| Printhead Options | 4 / 6 / 8 / 12 / 16 / 32 (max 4 rows) |

| Ink Compatibility | Pigment, Disperse, Sublimation, Reactive, Acid |

| Media Type | Elastic and non-elastic textiles |

| RIP Software | Neo-Stampa Optimum Digital Special Edition Caldera Textile Pro Enterprise |

| Max Media Weight | 551lbs / 17.7” diameter 250kg / 45cm diameter |

| Compressed Air | 0,6 MPa @ 2L / min |

| Variable Drop | 5 pl - 13 pl |

| Color Options | 4 color - 6 color - 8 color |

| Ink Tank System | Open System - 5kg capacity |

| Media Drying System | Industrial Drying System |

| Media Feeding System | Included Feeding System |

| Power Requirements | Single phase 220VAC 25A (for printer) Three phase 380VAC 32A (for dryer) |

| Graphical User Interface (GUI) | ODP Print 2 |

| Max Print Width | 80.7” | 205cm |

| Printer Dimensions | 225” x 91” x 87” | 572cm x 230cm x 222cm |

| Net Printer Weight | 6,173lbs | 2,800kg |

| Net Machinery Weight | 11,460lbs | 5,200kg |

Machine Features

- Smart automatic head cleaning system

- Separate industrial drying system included

- Industrial sticky belt activated with heated press roller

- Integrated spiral belt brushes to eliminate dirt build up

- Aluminium frame and double carriage rail

- Integrated industrial media feeding system

- Safety trigger system for printhead protection

- Closed design system for safe operation and reduced noise

- Magnetic linear motor rail for smooth carriage movement

- Large carriage for up to 32 heads in 4 rows

Printing Features

- Up to 8 colors per row for vibrant and colorful prints

- Easy to use practical washing unit for reduced down time

- Potential for uninterrupted 24/7 printing operations

- Low vibrations from strong frame for accurate dotting

- Reliable 1-pass printing at 800 m² / h

- Spare-parts and inks inventory at all locations

- In-house color specialist for customized color profiling

Included Machinery :

Printer

Fixation unit

Optional Machinery :

Feeding Unit

Centering Guide

Acumulator Winder